Shop Floor Control

Superior functionality makes viewing order information and production reports effortless

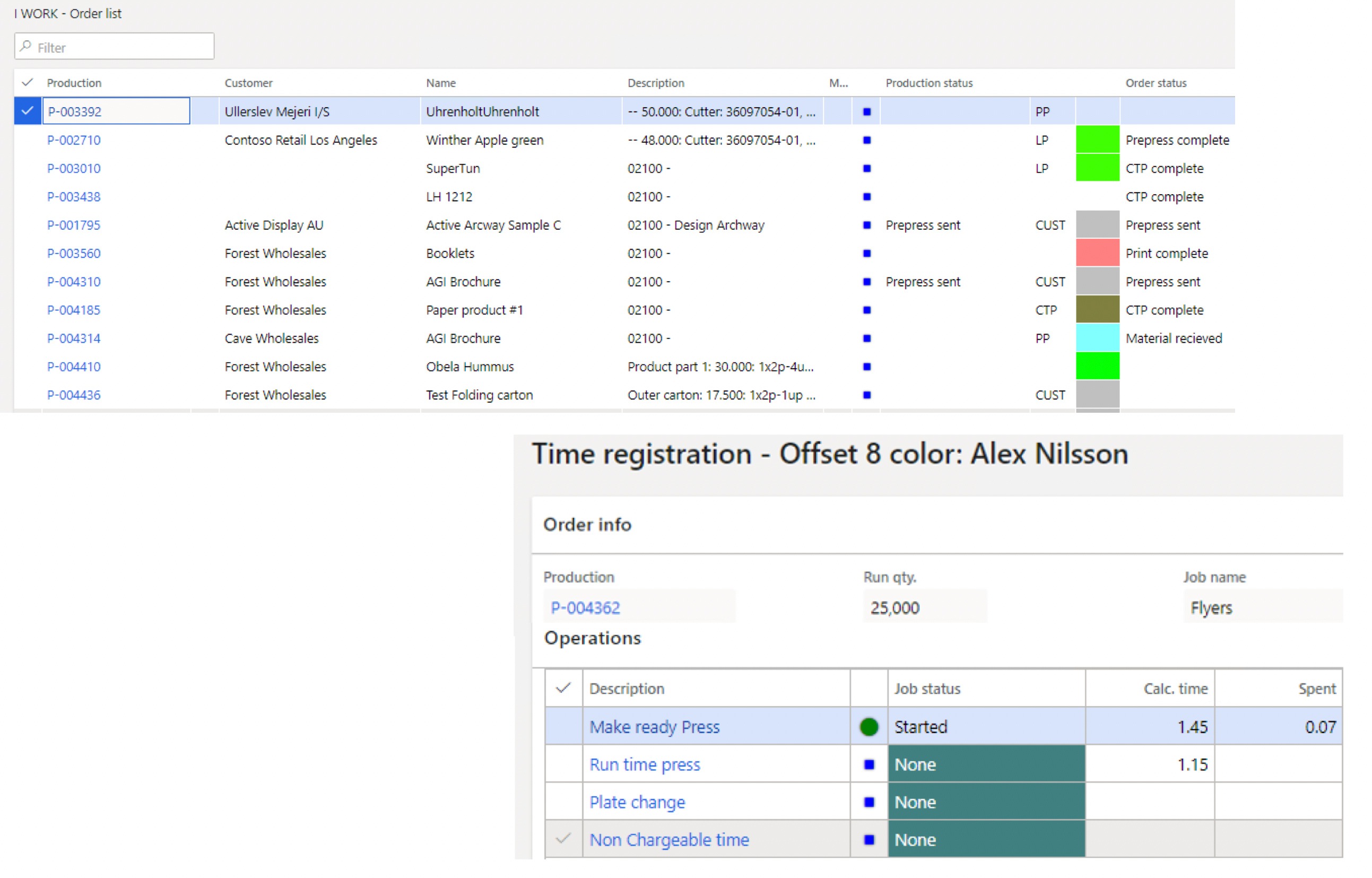

DynamicsPrint offers a simplified shop-floor user interface for confirming and reporting operations. Work instructions, quantity, and other production notes can be viewed and reported through digital work orders. DynamicsPrint’s shop-floor interface enables a paperless interface for production control and monitoring.

The system supports easy role and user-based configuration. The list can easily be modified with resources, employees, or orders with filtering options.

Shop Floor Management is developing and managing the shop floor operations, inventory, equipment, and workers are more essential than ever before. SFM is a management control instrument and primarily improves communication between employees and management, or other related operations.

The DynamicsPrint Shop Floor System provides a total overview for the operator. An order list of what has been scheduled for each work center, the job ticket with detailed specifications, and various communications, like Word documents, short messages, or attached images, are visible from the system, easy to access and are all available with one click.

Time and Material

The machine operator has all the information needed to complete the production. Start and Stop functionality provides a simple and secure registration of production data to cost accounting.

Registered time and material usage are automatically posted to the accounting system as “Work in Progress”.

Multiple Job Time Registration

The machine operator can select multiple jobs from the worklist, enabling time registration for more than one job. The actual time registration will be assigned to each job according to the estimated time.

Job Ticket

At any time, the operator can view the job ticket containing all relevant job information.

Job Plans

You have access to all job information, including the complete schedule for the selected job. If required, the operator can reschedule operations.

Job Routing

With one click, the operator gets an overview of the up and downstream operations.

Job Status

All actions are logged in the system with various job statuses, providing a complete real-time overview of all production operations.

Process Flow

The operator can generate reports such as pallet notes containing information about each pallet and the subsequent operation involving transportation and transfers.

Budget vs. Actual Cost

Data reported to the cost accounting will, through the post-calculation, be compared to the planned data from the order.

Actions from the shop floor system will show up in real time, in various places around the system. Customer service will have a clear picture of whether a job is on track, the planner team will see “work in progress” based on real time, and the supply chain will also have up-to-date information regarding materials that must be released to production.

All actions will be communicated to the relevant users. The system distributes data for everybody to make the right decisions and provides an overview of operations and their dependencies on other jobs.