As your business evolves, DynamicsPrint grows with you. Our ERP system is designed to scale seamlessly, accommodating increased workloads, new product lines, and expanding customer demands without compromising performance.

Whether you want to schedule on a very rough basis or if you need details for all your departments and work centers, DynamicsPrint gives you what you need.

Once the plan is defined, you can reschedule in a speedy and sophisticated way by moving a process and, with one keystroke, rescheduling all the associated operations within the job.

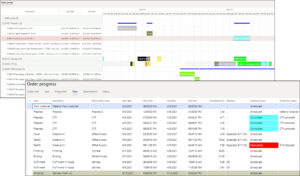

A form to create an overview of the work in progress gives you a quick insight and feel of the actual production status.

Deadlines

A simple plan can be created with deadlines. A deadline is a predefined date for which an activity or action is supposed to occur, such as receiving the materials, proofs, or deliveries.

Gross Plan

Gross planning checks the capacity for all the work centers involved in the job, and according to the deadlines (ex., delivery date), the job is scheduled. If any problems are identified, the system will warn you. This could be an overload in capacity or lack of materials to complete the job. The warning text is user-configurable, using a language everybody in the company can understand.

The CSR will have a complete overview of all operations in a natural process index order.

The estimated time consumption for each operation is listed on the screen and adjusted with an efficiency percentage for each machine.

Gantt Chart

The DynamicsPrint Gantt Chart gives you a real-time graphical production overview.

The friendly and easy-to-understand Gantt Chart timeline is the quickest and most practical way to plan, schedule, manage, and assign all your jobs with drag & drop simplicity.

Any changes in the schedule will immediately show up on the screen and will be considered as new jobs are scheduled.

Reschedule

One process in a route can easily be moved to a convenient date/time, and DynamicsPrint will automatically adjust the corresponding processes.

With an advanced filter, you can look up all jobs with common characteristics to create job batches.

Fine Plan

Review the order load for one work center, reschedule according to actual job statuses and generate a work-list for each operator or machine.

Buffers

To get a realistic plan, buffers can be inserted between the various operations to prevent that operation B starts immediately after operation A is finished. For example, it will be natural to insert a buffer between the finished printing and until cutting or folding has started.

Do you have any questions regarding DynamicsPrint?

Hyper Automation

Could you let DynamicsPrint organize the job-sequence more efficiently based on the configurations defined by yourself?

Let the system look up jobs with identical specifications, for example, the same paper, colors, etc., and a new plan will be presented to you with reduced make-over time and other efficiency benefits. Review the updated schedule and make modifications where it may be needed or approve the DynamicsPrint optimizer plan.

Decision Intelligence

At DynamicsPrint, we talk about lifts. A lift is defined as an action that directly improves the profit. A suggestion for a lift can be obtained by using artificial intelligence or regular algorithms.

We work with lifts in the scheduling module. The scheduling module has suggestions for lifts that reduce your production costs. You can sort the lifts after size in order to make the required actions using the most significant cost reduction first.